Modular Workholding

The Modular Workholding system by Jergens is a versatile and adaptable solution for securing parts in machining operations. With interchangeable components like subplates, risers, pallets, and top tooling, this system offers unprecedented flexibility. Its ability to optimize spindle positioning results in greater precision, reduced vibrations, better accessibility to workpiece surfaces, and increased tool life. The modular design allows for customization based on specific job requirements, improving operational efficiency and representing a smart investment.

The revolutionary Jergens modular workholding system stands out for its versatile and adaptable design that revolutionizes the way parts are secured in machining operations. This innovative system offers unprecedented flexibility thanks to its wide range of interchangeable components:

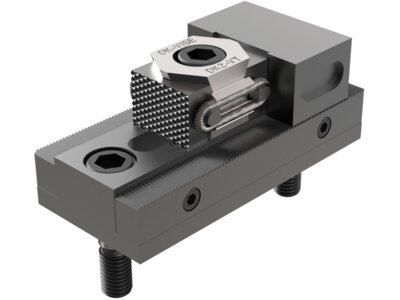

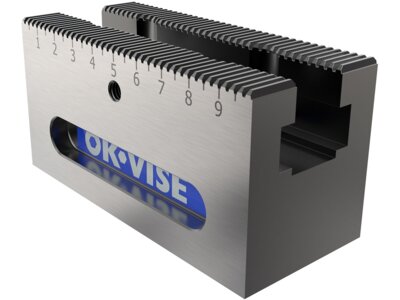

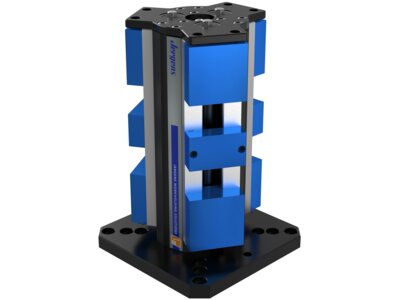

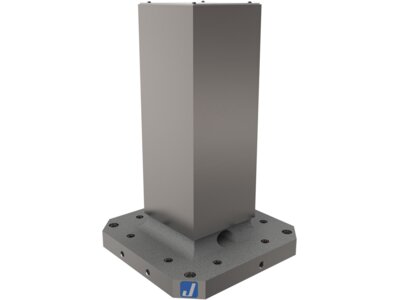

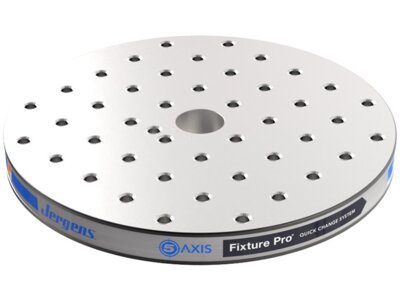

- Versatile subplates that provide a solid and precise mounting foundation

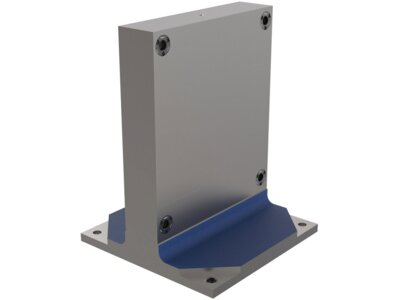

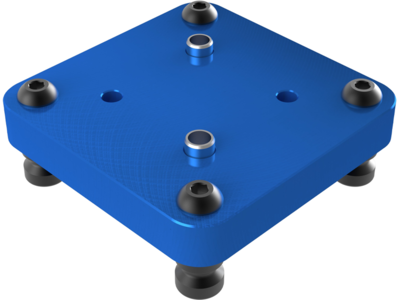

- Adjustable risers that allow optimization of working height according to specific requirements

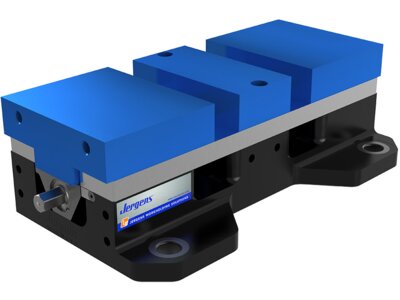

- Quick-change pallets that minimize downtime between operations

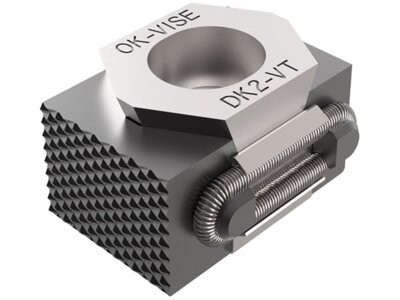

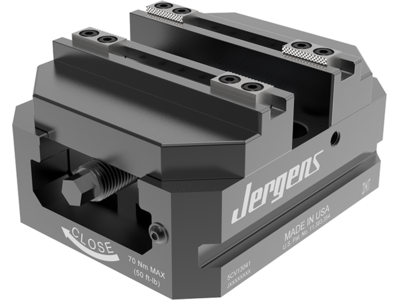

- Specialized top tooling designed for different applications

The most notable feature of this system is its ability to optimally position the spindle and cutting tool in relation to the workpiece. This results in:

- Greater machining precision

- Significant reduction in vibrations

- Better accessibility to all workpiece surfaces

- Optimization of production processes

- Increased tool life

The modular design allows the system to be configured according to the specific needs of each job, facilitating adaptation to different types of parts and machining operations. This flexibility not only improves operational efficiency but also represents a smart investment as components can be reused in different configurations.

Perfect for shops looking to maximize their productivity and precision, the Jergens system has become an industry benchmark in machining due to its adaptability and superior performance.